Blog

Non-sparking tools: Common Misconceptions You Need To Know

Non-sparking tools: Learn the basic concepts and be safe!

Non-sparking tool are tools made of special alloys that generate low energy sparks. The key principle to avoid an explosion is therefore to ensure that the energy of the spark a tool generates is lower than the ignition point of the gas in the atmosphere.

Read more to learn the basic concepts behind Non-sparking toolsand be safe!

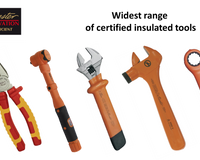

Insulated Tools: 5 Important Things You Need To Know

Non-sparking tools: Factors to Consider To Be Safe

The most common non-sparking alloys are Aluminum - Bronce (Al-Bron) and Copper – Beryllium (Cu-Be), but what should be the criteria when choosing one option or the other? Even if you are procuring or using non-sparking tools, it´s important that you keep these 4 factors in mind to maximize safety in your operations.

Read more to learn more about these important 4 factors.